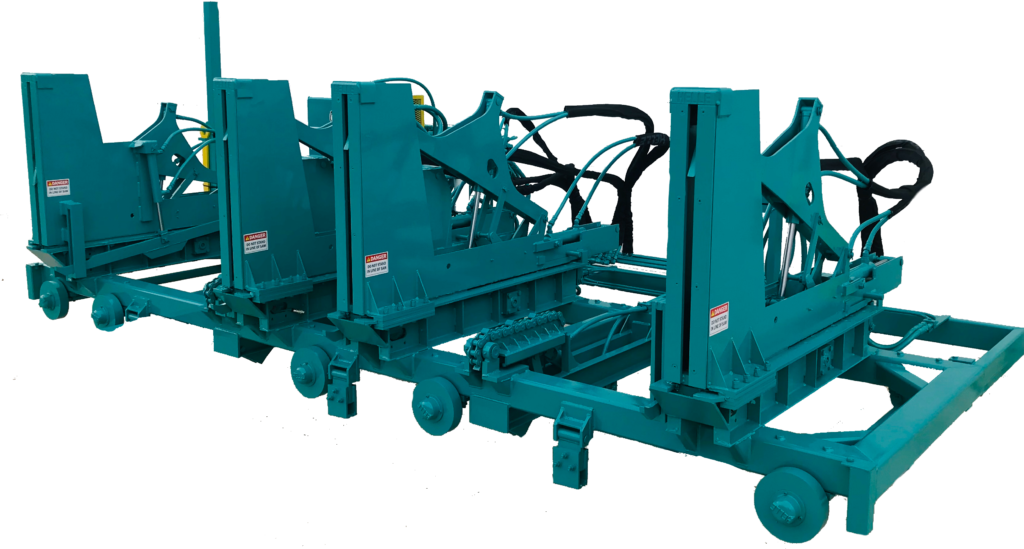

Carriages

All HELLE Carriages are custom built around the customers needs and can often be built to existing subframes.

All HELLE Carriages are custom built to our customer needs. Headblock spacing, opening and rail gauges are built to customer spec and customer needs. In most cases, the carriage frame can be made to fit your track, or we can custom build you a sub frame. Sawmill Hydraulics, Inc builds the entire Carriage from the ground up with your needs in mind. We build the pumping unit, cylinders, setworks and entire assembly all in house at our facility.

All HELLE Carriages are prewired, plumbed up and factory tested. The pumping unit on our carriages are self-contained and there are no hoses over the pantograph. HELLE was the pioneer in the double 80 roller chain, no rack and pinion. The guide wheels on each carriage are hexagon style wheels that wear up into the wheels to maintain accuracy. Our knee plates have wrap arounds and have replaceable wear plates made of fiber wear strips.

All HELLE Carriages are computer controlled. To adjust your thickness on your sets, all you do is flick a toggle switch in the cab, what could be easier? No more getting out of the cab and wasting time! HELLE pioneered the structural tube frame, making it much stronger than channel iron or I beam frames. The carriage frame can be made to fit your track, or we can make you a sub frame.

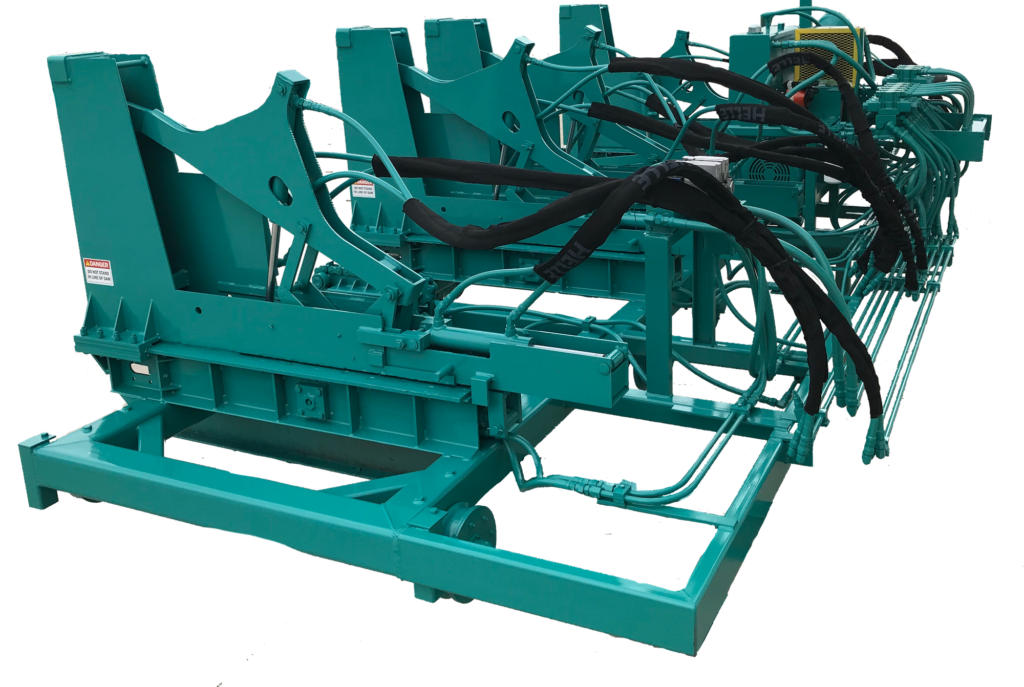

Facts About All Models Of HELLE Carriages:

- Non-arcing tong dogs with constant pressure when in log

- Top and bottom dogs taper with the dogs, not with the knees

- All valves are interchangeable

- Oil cooler and heater are standard

- Free standing hoses, like no other

- OEM Cylinders & Easy To Access– Heavy Duty Cylinders Built By Sawmill Hydraulics, Inc

- HELLE patented Log Flipper or Cant Kicker Available!

- All HELLE Carriages with Setshafts feature a high speed heavy duty hydraulic motor drive with two speed drive.

Standard Duty Carriage FACTS:

- 30” to 42” Opening

- Nylon Wheels Standard

- 5” X5” Frame With 2” Hex Axles

- 4” Taper Standard – 8” Optional

- All Valves Interchangeable

- Constant Pressure Dogs

- 10 Hp On Board Hydraulic Pumping Unit

- 1/2” Thick Knee Sides – 5/8” Thick Wearplates

- 1 15/16 Setshaft

- Solid One Piece Side Dogs

- 1” Thick Dogs

Heavy Duty Carriage FACTS:

- 40” to 60” Opening

- 6” X 6” Frame With 2 1/2” Hex Axles

- 8” Taper Standard

- All Valves Interchangeable

- Constant Pressure Dogs

- 15hp On Board Hydraulic Pumping Unit

- 5/8” Thick Knee Sides - ¾” Thick Wearplates

- High Speed Hydraulic Drive

- Triple 80 Chain

- 2 3/16” Set Shaft

Linear Carriage FACTS:

- The HELLE Linear Carriage is available in Standard or Heavy Duty.

- No Additional Backwall Clearance

- 2” Bore Cylinder

- Measuring Probe Is Built Into The Cylinder Fast!

- Available With Scanning Or Without